sgchap3

Full Member

Anyone else ever have any problems after having a aftermarket exhaust and/or headers installed. I've had two different O2 senors go off in the last month after having my exhaust and headers changed to Corsa and Dynatech.

I also have it on the dyno and costum tuned.

The guys are really good and I stand behind thier work. Is it possible that hurt the O2's while they were tuning it and is it just in need of new ones or is this something that will keep happening

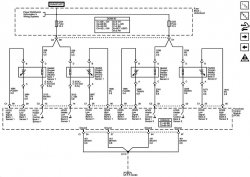

The only good thing is the dealer has no questions and replaces the O2 senors whatout any questions asked but its getting to be a pain and there are like 8 senors in the system. Does that mean 6 more trips to the dealer?!?

Any input please, thanks

I also have it on the dyno and costum tuned.

The guys are really good and I stand behind thier work. Is it possible that hurt the O2's while they were tuning it and is it just in need of new ones or is this something that will keep happening

The only good thing is the dealer has no questions and replaces the O2 senors whatout any questions asked but its getting to be a pain and there are like 8 senors in the system. Does that mean 6 more trips to the dealer?!?

Any input please, thanks

IT"S BACK ON! Can't believe it! I took a trip to Philly this weekend and half way down my 'engine' light came on again!!!

IT"S BACK ON! Can't believe it! I took a trip to Philly this weekend and half way down my 'engine' light came on again!!!