turbojimmy

Full Member

So I've had a P0420 for years. At first it was intermittent, but then became a solid code a couple of years ago. In NJ we have to go through emissions inspection every 2 years. The truck is quite literally falling apart from rust, but mechanically it's fine. Runs good, 4WD works, so I figured I'd invest in the exhaust fix. I got a new set of cats from Eastern Catalytic and a Gibson exhaust system (which is quite nice and inexpensive). I also got 4 new O2 sensors.

With the new exhaust and O2 sensors installed, I unhooked the battery to recalibrate the fueling and cleared the codes. One by one the OBD-II monitors cleared and I was ready for emissions inspection. It passed, so I got 2 more years out of it so long as the body holds up.

At 125 miles since the exhaust fix the CEL came back on. It's a P0430 - cat on bank 2. No other codes. I cleared it, but it comes right back as soon as the cat OBD-II monitor runs. So...how do I diagnose? Eastern Catalytic won't process a warranty claim without a "trained mechanic" diagnosis which we all know consists of plugging it in and seeing a P0430 code. I'm not paying for a diagnosis.

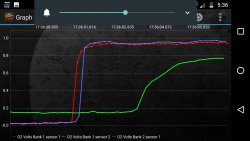

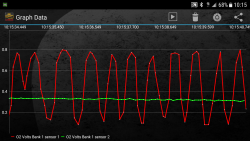

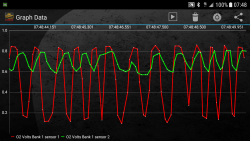

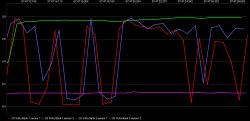

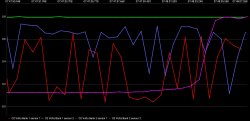

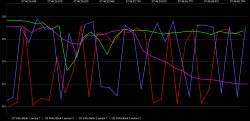

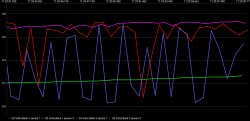

I have a scanner that shows me expected and actual cat efficiency. I don't know if that's enough evidence for them. Not sure if swapping the new O2 sensors to bank 1 would make sense just to see if I get a 420 instead (indicating an O2 sensor problem rather than the cat itself).

It sucks because I was really enjoying the way the truck runs with the new parts - particularly the ability to remote-start it which I haven't been able to do in years.

With the new exhaust and O2 sensors installed, I unhooked the battery to recalibrate the fueling and cleared the codes. One by one the OBD-II monitors cleared and I was ready for emissions inspection. It passed, so I got 2 more years out of it so long as the body holds up.

At 125 miles since the exhaust fix the CEL came back on. It's a P0430 - cat on bank 2. No other codes. I cleared it, but it comes right back as soon as the cat OBD-II monitor runs. So...how do I diagnose? Eastern Catalytic won't process a warranty claim without a "trained mechanic" diagnosis which we all know consists of plugging it in and seeing a P0430 code. I'm not paying for a diagnosis.

I have a scanner that shows me expected and actual cat efficiency. I don't know if that's enough evidence for them. Not sure if swapping the new O2 sensors to bank 1 would make sense just to see if I get a 420 instead (indicating an O2 sensor problem rather than the cat itself).

It sucks because I was really enjoying the way the truck runs with the new parts - particularly the ability to remote-start it which I haven't been able to do in years.