Hello all,

My first post here and thank you for the add.

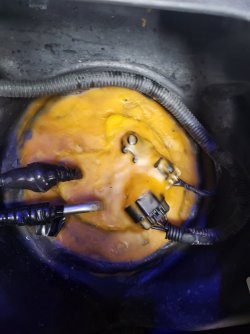

My Avy is a 2011 with a current mileage of 235k KM (Canadian) (146k Miles). I recently replaced the entire fuel pump assembly (aftermarket), At that time, I noticed that the top of the assembly was rusted out and there was a hole drilled for a wire that directly led to the fuel level sensor inside the pump and jumped to the wiring harness outside of the pump. I investigated the wiring and found that there was a connector that was corroded and I replaced it and hooked everything back up and reinstalled the tank.

On my first fill up, the gauge seemed to operate properly by indicating that it was a full tank (I had done the service with less than a quarter tank). As I drove, the tank obviously began to empty. When the low fuel light came on, I went to the gas station and filled up. Upon fill up, I noticed that I only put in 84 litres where the tank has a capacity of 117 litres according to factory specs. 33 litres were still in the tank. I didn't think this was normal as whenever I've had the low fuel light go in, I would have about another 100km left for distance before I call CAA.

I did a calculation and found that my fuel economy was horrible. 19l/100km. I went through another month or so and did some calculations for range on the trip and was very close to coming to within 10 litres left on fill up but still getting about the same economy. On board DIC said that my variable running cylinders were working (going from 4 cyl to 8 cyl). I do get EVAP errors of P0442 and P0455 (small and large EVAP leaks detected resp.). I recently (within the last week), I am now getting P0451 EVAP System Pressure Sensor/Switch Circuit Range Performance error.

I have not replaced the fuel cap as the dealer does not have one and one is on order. Currently have an aftermarket on in from about a year ago and they suck.

On my ODBII reader, the fuel level input was at 14% when there was 33 litres left in the tank and low fuel warning on the dash. At 14%, there should be about 16 litres in the tank which kind of makes sense that the low fuel warning came on. I should also add that EVAP System Vapor Pressure is in the negatives; I believe severe at -400's, there should never be negative pressure, should there?

My question is/are

Any help would be greatly appreciated.

Thank you!!

My first post here and thank you for the add.

My Avy is a 2011 with a current mileage of 235k KM (Canadian) (146k Miles). I recently replaced the entire fuel pump assembly (aftermarket), At that time, I noticed that the top of the assembly was rusted out and there was a hole drilled for a wire that directly led to the fuel level sensor inside the pump and jumped to the wiring harness outside of the pump. I investigated the wiring and found that there was a connector that was corroded and I replaced it and hooked everything back up and reinstalled the tank.

On my first fill up, the gauge seemed to operate properly by indicating that it was a full tank (I had done the service with less than a quarter tank). As I drove, the tank obviously began to empty. When the low fuel light came on, I went to the gas station and filled up. Upon fill up, I noticed that I only put in 84 litres where the tank has a capacity of 117 litres according to factory specs. 33 litres were still in the tank. I didn't think this was normal as whenever I've had the low fuel light go in, I would have about another 100km left for distance before I call CAA.

I did a calculation and found that my fuel economy was horrible. 19l/100km. I went through another month or so and did some calculations for range on the trip and was very close to coming to within 10 litres left on fill up but still getting about the same economy. On board DIC said that my variable running cylinders were working (going from 4 cyl to 8 cyl). I do get EVAP errors of P0442 and P0455 (small and large EVAP leaks detected resp.). I recently (within the last week), I am now getting P0451 EVAP System Pressure Sensor/Switch Circuit Range Performance error.

I have not replaced the fuel cap as the dealer does not have one and one is on order. Currently have an aftermarket on in from about a year ago and they suck.

On my ODBII reader, the fuel level input was at 14% when there was 33 litres left in the tank and low fuel warning on the dash. At 14%, there should be about 16 litres in the tank which kind of makes sense that the low fuel warning came on. I should also add that EVAP System Vapor Pressure is in the negatives; I believe severe at -400's, there should never be negative pressure, should there?

My question is/are

- Would the EVAP errors (including the new P0451) have any standing on the incorrect reading?

- Aftermarket fuel pump assembly a POS and stick with OEM?

- What would be a logical electrical outlet test on the fuel level sensor (OHM reading) to see if the "new pump" is faulty?

- Is there a control module fault possible?

- The negative EVAP pressure fault?

Any help would be greatly appreciated.

Thank you!!

Last edited: